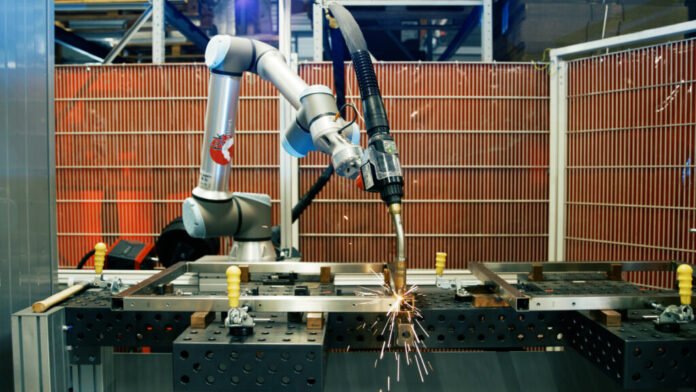

India’s manufacturing sector is undergoing a quiet but decisive transformation. As the country pushes toward its ambition of becoming a global manufacturing hub, productivity, quality, and competitiveness have become non-negotiable. Among the technologies driving this shift, robotic welding stands out as a powerful enabler—reshaping shop floors, redefining workforce skills, and setting new benchmarks for efficiency across Indian industry.

The Productivity Imperative

Indian manufacturers face intense pressure from both domestic and global markets. Rising input costs, tighter delivery timelines, and growing quality expectations have exposed the limitations of manual welding processes. Variability in weld quality, dependence on skilled labor availability, and safety concerns often lead to rework, downtime, and inconsistent output.

Robotic welding directly addresses these challenges. Automated systems deliver consistent welds at higher speeds, operate continuously with minimal fatigue, and reduce material wastage. For industries such as automotive, heavy engineering, construction equipment, railways, and shipbuilding, this translates into higher throughput and predictable production schedules—critical for scaling operations and meeting export standards.

Accelerating Adoption Across Sectors

Historically, robotic welding in India was largely confined to large automotive OEMs and tier-1 suppliers. That is changing rapidly. Falling costs of industrial robots, improved ease of programming, and the availability of locally supported automation solutions have brought robotic welding within reach of mid-sized manufacturers.

The government’s “Make in India” initiative and production-linked incentive (PLI) schemes have further accelerated investment in advanced manufacturing technologies. As global OEMs demand world-class quality from Indian suppliers, robotic welding is no longer a luxury—it is becoming a requirement for participation in high-value supply chains.

Quality, Consistency, and Compliance

One of the most significant productivity gains from robotic welding comes from consistency. Robots follow precise, repeatable paths, ensuring uniform penetration, bead shape, and strength across thousands of components. This consistency reduces inspection time, lowers rejection rates, and improves compliance with international standards such as ISO and automotive quality norms.

In sectors like pressure vessels, pipelines, and structural fabrication, consistent weld quality directly impacts safety and long-term reliability. By minimizing human variability, robotic welding strengthens trust in Indian-manufactured products on the global stage.

Workforce Transformation, Not Replacement

A common concern around automation is job displacement. In reality, robotic welding in India is driving workforce transformation rather than elimination. Skilled welders are increasingly being upskilled into robot operators, programmers, and maintenance technicians. This shift improves working conditions by reducing exposure to heat, fumes, and repetitive strain while creating higher-value technical roles.

Training institutes and industrial training centers are beginning to incorporate robotic welding modules into their curricula. This alignment between industry and skill development is essential if India is to build a future-ready manufacturing workforce.

Overcoming Barriers to Implementation

Despite its advantages, challenges remain. High initial capital investment, especially for small and medium enterprises (SMEs), can be a deterrent. Integration with existing production lines, variability in component design, and limited in-house automation expertise also slow adoption.

However, flexible robotic systems, collaborative robots (cobots), and leasing or automation-as-a-service models are lowering entry barriers. System integrators and robot manufacturers are increasingly offering end-to-end solutions—covering design, simulation, installation, and training—making robotic welding more accessible than ever.

Data, Connectivity, and Industry 4.0

Robotic welding is also a gateway to smart manufacturing. Modern systems generate real-time data on weld parameters, cycle times, and equipment health. When integrated with Industry 4.0 platforms, this data enables predictive maintenance, process optimization, and traceability.

For Indian manufacturers aiming to compete globally, this digital layer is crucial. Productivity is no longer just about speed; it is about insight, control, and continuous improvement.

Forging the Future

As India’s manufacturing ambitions grow, robotic welding will play a central role in forging the future of industrial productivity. It empowers manufacturers to scale efficiently, deliver consistent quality, and integrate into global value chains. More importantly, it signals a shift in mindset—from labor-intensive production to technology-driven excellence.

By embracing robotic welding, Indian industry is not just automating a process; it is laying the foundation for a more resilient, competitive, and future-ready manufacturing ecosystem.