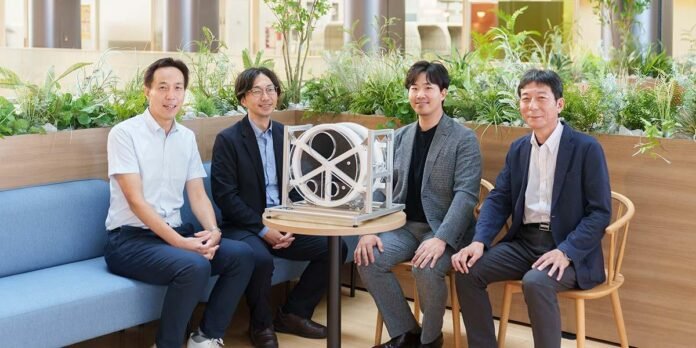

Expected annual energy savings of 20 million yen per drying equipment unit–. The compact VOC removal system developed by Murata Manufacturing (“Murata”) is the result of an innovative technology that reduces environmental impact while increasing factory efficiency. The adoption of a “one-by-one” system that can be installed in a distributed manner for each piece of production equipment enables significant energy savings for cleanroom humidity and temperature adjustments. In addition, the system also enables increased layout flexibility when replacing existing large-scale VOC removal systems or building new factories. At the same time, creating a compact, high-efficiency rotor, which is the heart of a VOC removal system, was essential for realizing a one-by-one system. In response, Murata worked to overcome these challenges by applying its accumulated technologies.

Thinking about environmental impact reduction by combining production equipment and exhaust treatment facilities

Murata is developing a new technology that increases the efficiency of exhaust treatment for drying equipment (drying ovens) used at production bases in various locations. Mr. Awaya of the Corporate Technology & Business Development Unit, explains that this initiative aims to contribute to society through external sales after achieving a reduction in the environmental impact of the company’s own manufacturing activities.

“Drying equipment is used in many manufacturing industries. Drying equipment heats up and removes solvents and moisture, etc. from coating liquids, films, metal foils and other materials adhering to various components and materials. Heat is required during removal, which consumes energy. In addition, when the removed substances contain volatile organic compounds (VOC), energy is also required to operate the equipment for recovering and detoxifying the VOCs. The technology developed by Murata applies a concept which differs from the conventional process of concentrating and removing the VOCs in order to achieve energy savings.” (Awaya)

Murata has been working for some time on ways to reduce the environmental impact of manufacturing. According to Mr. Shigaki of the Corporate Technology & Business Development Unit, “To realize a decarbonized society, we are planning and implementing around 500 energy-saving measures per year while setting targets for net-zero greenhouse gas (GHG) emissions from our own operations by 2040 and net-zero GHG emissions including our supply chain by 2050. In addition, we are also taking action from the perspective of international environmental initiatives such as deciding to shift the RE100 target of using 100% renewable energy for the power used in our business activities from 2050 to 2035.”

Such initiatives were advancing across the company, but there was still room for improved energy-savings at manufacturing sites. Mr. Sanada of the Ceramic Capacitor Business Unit recalls, “Progress had been made on cost reduction and rationalization in the production equipment, manufacturing lines, and processes. However, we felt that there was still more that we could do regarding the energy required to operate the equipment, and energy saving in facilities and infrastructure. For example, when we thought about the production process and exhaust treatment facility, which we had previously considered separately, as a set, we realized that there was the potential to achieve further energy savings.”

The team set their sights on the exhaust treatment process for drying equipment. “The factory originally had equipment for treating exhaust gases from the drying equipment, etc., and the need for energy saving had been highlighted. Traditionally, the exhaust for the entire factory was concentrated in one location and treated by a centralized detoxification facility. The treatment facility was large enough to be a building and consumed a vast amount of energy.” (Sanada). Generally speaking, centralized treatment in a central facility is thought to be highly efficient in terms of energy and treatment. However, they achieved unprecedented results with the compact distributed installation type (one-by-one) concept, which is the complete opposite of the centralized approach. The centralized approach consolidating VOC treatment for multiple production equipment requires full operation regardless of the operating status of each individual production equipment. Therefore, such an approach tends to be over-specified and consumes more energy than necessary. For example, when there are multiple temperatures, humidity levels, and concentrations, the conventional centralized system must be operated under conditions that correspond to the maximum temperature, maximum humidity, and maximum concentration. In contrast, installing a one-by-one system enables the VOC removal system to be appropriately controlled according to the operating status of each individual production equipment.

A compact VOC removal system with expected benefits from multiple approaches

Let’s briefly review the operating principles of a VOC removal system. The core of the system is a rotor that adsorbs and desorbs the VOCs as it slowly rotates inside the system. The interior of the rotor is coated with a VOC adsorbent that is a porous material, and the VOCs in the exhaust gas are adsorbed onto the rotor by passing the exhaust gas containing VOCs generated by drying equipment through the rotor.

Next, the rotor is heated to a high temperature by rotating to desorb, concentrate, and exhaust the VOCs. Having removed the VOCs, the rotor cools down and returns to the temperature inside the drying equipment to restart the adsorption process. This principle is identical to the one used in centralized equipment in which a large-sized rotor rotates and repeats the processes of adsorption, thermal desorption, and cooling. To install a one-by-one VOC removal system, it was essential to miniaturize this rotor.

Awaya explains that adopting a compact VOC removal system provides a wide range of benefits. “The power consumption of a centralized VOC removal system is extremely high, so miniaturizing the equipment will reduce power consumption. When equipment needs to be replaced in the future, installing a compact VOC removal system for each piece of production equipment can also minimize the existing process layout. When building a new factory, it also reduces the need for piping ducts to a centralized VOC removal system, which increases the layout flexibility.” (Awaya)

Miniaturizing the VOC removal system and installing it close to equipment also provides benefits that cannot be achieved with centralization. In a centralized system, the VOCs are concentrated and detoxified before releasing the exhaust gas into the atmosphere. On the other hand, a compact VOC removal system can be placed near the production equipment, which makes it possible to return the exhaust gas to the cleanroom. Because the heated exhaust gas can be reused, the energy used to adjust the temperature and the humidity of the air via heating inside the production equipment can be significantly reduced, which further increases the energy savings.

One additional benefit of one-by-one installation is that complete VOC removal is no longer required. “Exhaust gases containing VOCs must ultimately be released into the atmosphere after being completely detoxified in a centralized system. Therefore, a large amount of energy is used. However, if the exhaust gas is directly returned to the production equipment’s drying equipment with a one-by-one system, instead of completely detoxifying the exhaust gas, it is sufficient to remove the VOCs to a concentration that is suitable for VOC drying. This leads not only to equipment-based energy savings but also miniaturization.” (Sanada)

Applying Murata’s accumulated technologies to successfully miniaturize the rotor

The compact VOC removal system developed by Murata required a miniature rotor of less than one meter in size. It was not enough to simply make it compact, as the company had to develop a rotor that was capable of adsorbing and desorbing VOCs with high efficiency even at a small size.

“The rotor features a honeycomb-shaped structure with minute holes, and a thin film of adsorbent in those holes to adsorb the VOCs. We devised a structure that creates a film to efficiently adsorb the VOCs by passing the exhaust gas through the rotor holes. This applies the thin film technology used in Murata’s core multilayer capacitor products.” (Sanada) Various technologies that have been accumulated within Murata were utilized to miniaturize the rotor.

Awaya further explains, “When there are variations in the thickness of the coating film or the particle dispersion inside the film, the air does not efficiently flow through the honeycomb structure, and the gas adsorption efficiency decreases. We developed a technology for refining and dispersing the slurry, and control it so that it can be evenly applied.” Several breakthroughs occurred to make the compact VOC removal system a reality.

The development of the compact VOC removal system started within the Capacitor Business Unit. When the development plan for the compact VOC removal system was shared with the business unit’s head of equipment development, it was praised as a “technically sound idea” and received development support. “Being described as ‘sound’ at this time meant that it could be explained without contradicting fundamental principles. In addition, we were able to present the economic and business merits, which helped the development proceed smoothly.” (Sanada) Consequently, Murata developed an ultra-compact VOC removal system that uses a rotor that is approximately one meter long. Depending on the concentration of VOCs contained in the exhaust gas, it is capable of removing 90% or more of the VOCs during treatment. Using a rotor that incorporates an adsorbent material compatible with a diverse range of VOCs expands the scope of application and enables adoption across many industrial sectors without customization.

Saving energy by making a heat source unnecessary and reducing 20 million yen in costs per year

Incorporating the developed compact VOC removal system into manufacturing processes is expected to have a significant effect. Sanada explains, “Internal verification indicates that we can expect to achieve significant energy savings of 20 million yen per year for one drying equipment unit by linking the exhaust treatment facility with the production equipment.” The temperature of the drying equipment needs to be heated from room temperature to about 100°C, and an external heat source was previously used. Recycling the exhaust gas heated by the compact VOC removal system has the effect of significantly reducing the energy consumption of the heat source. In addition, the cost required to install the equipment can be reduced compared to the large-scale centralized approach. “Generally speaking, environmental products are said to require eight to ten years to recover the costs of initial investment, but the recently developed compact VOC removal system is expected to recover the costs over three to seven years. We believe that we have achieved a product with high economic value by recycling the air and heat.” (Shigaki)

Several benefits are also expected on the environmental side. The GHG Protocol calculates the reduction in GHG emissions referring to direct emissions by a business as “Scope 1,” indirect emissions by other companies in the supply chain as “Scope 2,” and all other emissions as “Scope 3.” The compact VOC removal system developed by Murata is believed to be effective at addressing both Scope 1 and Scope 2 emissions. “The improved combustion efficiency of the compact VOC removal system contributes to Scope 1 by reducing the CO2 generated by combustion. If we can reduce the power used in heating and humidity adjustment, etc., it will also contribute to reducing Scope 2 emissions caused by power. It is an unusual piece of equipment that can address both scopes in one device.” (Awaya)

The company is currently considering the introduction of several hundred units of the compact VOC removal system, which was developed in this manner, in several processes at its own production sites from 2025. With the expectation that it will save energy and reduce GHG emissions while simultaneously reducing costs, the company is steadily proceeding with the introduction steps. By promoting internal use and taking into account the know-how, quality, and production response gained through actual operation, the company is planning to conduct an external PoC (proof of concept) in 2026. Later, they hope to begin full-scale external sales of the system as a product in 2027.

All of the team members interviewed for this article emphasized that, “this product can be deployed across a wide range of industries that use drying equipment.” For example, it is expected to be deployed in growth industries such as batteries, electronic components, automobiles, and semiconductors, etc. They were unanimous in their enthusiasm for external sales saying, “We hope to expand sales of this equipment, which balances both energy savings and environmental measures, both in Japan and overseas.”

The new VOC removal system was born from the accumulated technologies that Murata has cultivated with the goal of solving its own challenges. As a concrete example of a new form of manufacturing by Murata’s balancing of both energy savings and environmental response, the company will drive innovation across the entire industrial world.